1

Kwinana Grain Terminal

Viewed from Rockingham Beach, this terminal was opened in 1976 and receives grain from nearly 120 country receival points throughout the Kwinana zones.

|

2

Kwinana Grain Jetty

Grain is discharged from storage via 4 shipping conveyors to the grain jetty. The 4 ship loaders can discharge grain onto an awaiting ship at a combined rate of 5,000 tonnes per hour (tph).

|

3

Kwinana Grain Terminal and Storage

Grain is transported mainly by rail to the terminal at Kwinana which has a current storage capacity of more than one million tonnes. The terminal can receive grain at 4,000 tonnes per hour (tph) from rail.

|

4

Entrance to Administration, Offices and Control Room

|

5

Main Workhouse (74 metres)

We are going up to the Lookout Platform above the 12th Floor.

|

6

Stepping out onto Lookout Platform

Inland view towards Kwinana, from Lookout Platform above 12th floor.

|

7

Kwinana Industrial Area

Moving anti-clockwise around the Lookout.

|

8

Kwinana Industrial Strip along Cockburn Sound

|

9

Kwinana Industrial Strip along Cockburn Sound

Note Grain Truck turning into the Grain Terminal entrance.

|

10

Kwinana Industrial Strip along Cockburn Sound

|

11

Kwinana Industrial Strip along Cockburn Sound

A closer view showing Kwinana Jetty (foreground) and Wells Park.

|

12

Shipping in Cockburn Sound

|

13

Closer view of the Industrial area

|

14

Closer view of the Industrial Smog

|

15

Car and Horse Float in Carpark below

|

16

Horse Beach

Horse owners use this beautiful beach to train and exercise their horses.

|

17

Kwinana Grain Jetty

Length of Shipping Transfer Gallery 752 m. Length of Kwinana Grain Jetty 291 m.

|

18

Council Tractor and Beach Cleaning Machine

|

19

The two Horses returning along the Beach

|

20

Mussel Farm beside the Kwinana Grain Jetty

|

21

Closer view of the Mussel Farm

The grain dust from the ship loading operations provides nutrients for the mussels.

|

22

Kwinana Grain Jetty with Garden Island beyond

First Shipment was 5 July 1977 on Mexican Gulf", 44,985 t. Largest Cargo was 22 November 1979 on "MV Bjorgholm", 78,507 t.

|

23

Ship loading at Kwinana Grain Jetty

|

24

Zoomed above the Grain Jetty to Garden Island

|

25

Shipping in Cockburn Sound

|

26

Kwinana Jetty and Wells Park

The cut-down and filled hull of the wrecked 'SS Kwinana' can be clearly seen above. See photos 80-83 for a ground-level view.

|

27

Kwinana Industrial Strip with Perth Skyline on Horizon

|

28

View West to Point Peron and Garden Island Causeway

|

29

Palm Beach at Rockingham

Note construction of replacement Palm Beach Jetty at left. Indian Ocean on the horizon.

|

30

Rockingham High-rise Buildings and foreshore

|

31

The Rooftops of Rockingham

|

32

City of Rockingham Council Offices and Belltower

Note new Cinema under construction behind the orange roof of Council Offices.

|

33

Overlooking Cooloongup

New Rockingham Train Station is the white roof just above the fence. Cooloongup Supa IGA is just behind it.

|

34

Rockingham Light Industrial Area through the Fence

|

35

Light Industrial Area through Fence, new Housing beyond

|

36

The Granary Museum

A very informative and interesting display of equipment and methods used in the storage and shipment of grain.

|

37

Reception Area

Seating and tables made from corrugated iron which was the main material used for grain storage facilities.

|

38

Scales on Display

|

39

Bags of Grain

Prior to the introduction of Bulk Handling, all grain was transported in Hessian Bags.

|

40

Replica of Ship on the Dock

|

41

Bags on the Wharf

During the 1920's gangs of 'wheat lumpers' were employed to weigh bags of wheat and manually load them onto ships at Fremantle. Later, a series of bag elevators, conveyors and chutes aided the lumper in handling the grain from wharf to the ship's hold where they were manually stowed. This took 8-10 days to load 8,000 tons or 96,000 bags.

|

42

Scales to check Bag Weight

|

43

Railway Wagon used to Transport Bagged Wheat

|

44

The Grain Trains

Railways carried bagged wheat on flat topped wagons until the Co-operative paid for the alteration of 200 existing steel wagons to carry bulk wheat. In 1950 the Railway Dept took over the maintenance and commenced building suitable bulk wagons.

|

45

Model of Bulk Grain Wagon

Today's grain train consists of specially designed 'bottom discharge' aluminium tankers. Railway locomotives pulling up to fifty five tankers, each carrying up to 70 tonnes of grain can be seen transporting grain from the wheatbelt to the port.

|

46

Wheat Lumpers

In the 1920's and early 30's hundreds of young men carried 180 lb bags of wheat on their backs for a few cents per hour to build wheat stacks at various railway sidings in the wheatbelt.

|

47

Lumpers were Competitive and Proud of their Skills

Bill Cestrilli took up the challenge at Miling in 1927 and broke the record when he single handedly lumped and stacked 1,725 bags of wheat in 8 hours.

|

48

Portable Elevator beside Wheat Bin

|

49

Model Portable Grain Storage Bin and Portable Elevator

|

50

Farm Transport of Grain

|

51

Farm Transport of Grain

This 1926 Chevrolet Truck was used by the Muhs' Family to transport bagged wheat to the Nungarin Receival Point.

|

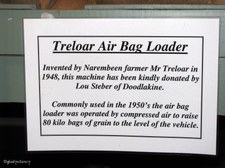

52

Treloar Air Bag Loader

|

53

Treloar Air Bag Loader

Invented by Narembeen farmer Mr Treloar in 1948. Commonly used in the 1950's the air bag loader was operated by compressed air to raise 80 kilo bags of grain to the level of the vehicle.

|

54

The Grain Weighbridge, new and old

|

55

A Water Bag and Billy Tea

Life for the wheat lumper working in the bush in the 1930's was rough and ready. Home was usually a tent with few bare essentials like an all purpose basin, a water bag, billy can box table, a few jars and a hurricane lamp. The pay was about one pound four shillings and nine pence a day. Despite harsh conditions, most had fond memories of these times with nights spent around the camp fire with billy tea and listening to the sounds of the bush.

|

56

Typical Wheat Lumper's Tent which was Home in the Bush

This campsite is a reconstruction, taken from one of Lance Ainsworth's photographs, and was where he lived whilst employed by the Company as a member of one of the construction gangs building the new iron and timber storages in the Corrigin District.

|

57

Bush Camp

Bicycle was often the only means of transport for the wheat lumpers.

|

58

Lance A Ainsworth

Campsites such as the one displayed were familiar scenes throughout the wheatbelt in the early 1930's and were home to many an employee working for the newly formed Co-operative. This campsite is a reconstruction, taken from one of Lance Ainsworth's photographs, and was where he lived whilst employed by the Company as a member of one of the construction gangs building the new iron and timber storages in the Corrigin District.

|

59

Bush Kitchen

Billy and saucepan on cut-down drum for fireplace, camp oven and axe for chopping wood.

|

60

The "Speedy" Moisture Tester

|

61

Set of Weights

|

62

Collection of Memorabilia

|

63

Sets of Scales

|

64

Collection of Seed Samples

Wheat, Barley, Oats and Miscellaneous Seeds.

|

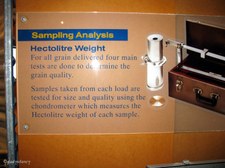

65

Sampling Analysis

Hectolitre Weight. For all grain delivered four main tests are done to determine the grain quality. Samples taken from each load are tested for size and quality using the chondrometer which measures the Hectolitre weight of each sample.

|

66

Chondrometer Bushel Measure and Certificate for Machinery

|

67

Scale Model of Fremantle Grain Terminal

Model of the 4,000,000 Bushel Grain Terminal, Fremantle. Construction commenced on 30 January 1962 when the first pile was driven by the Hon The Minister for Agriculture of Western Australia, the Hon CD Nalder MLA.

|

68

CBH Storage Facilities

Since the bulk handling experimental phase in the 1932/33 season, there has been a steady evolution in storage types and design over the years. From rudimentary corrugated iron and timber structures of the 1930's to the concrete and steel horizontal storages, as well as vertical silos, CBH has developed and built according to projected grain production estimates for each operational zone.

|

69

Evolution of CBH Storage Facilities

|

70

Which Grain?

Grains and their uses.

|

71

Scale Model Metro Grain Centre at Forrestfield

|

72

Safety and First Aid

|

73

Protective Suit

|

74

The Granary Weevil

The Granary Weevil drills into the grain but lays its eggs inside the grain kernels. The eggs hatch and the pupae continue growing until, as adults, they eat their way out, destroying the grain in the process.

|

75

Pest Control Department

The Company's Pest Control Department is integral to CBH's primary objective, to provide insect and pesticide residue free grain. To achieve this the Company employs chemists and technicians to staff their laboratories, and teams of qualified staff who operate out in the field.

|

76

Display of Corn Dolly Craftwork

|

77

Seed Box of Sunshine Seed Fertilizer Drill

|

78

Construction Achievement Award 1974

Australian Federation of Construction Contractors, Construction Achievement Award 1974, awarded to Frankipile Australia Pty Limited for outstanding performance on the construction of the foundation works for Co-operative Bulk Handling Limited - Kwinana Grain Terminal -

|

79

Leaving the Kwinana Grain Terminal

|

80

Kwinana Jetty from wreck of 'SS Kwinana'

Grain Jetty on horizon.

|

81

'SS Kwinana' at rest on Kwinana Beach

During a gale on 30 May 1922, the 'SS Kwinana' broke her moorings and was blown ashore near Rockingham to become a total wreck. The name of the 'SS Kwinana" has been perpetuated in the naming of the beach where she lay as a wreck.

|

82

Rusting Hull of 'SS Kwinana'

The 'SS Kwinana' was a 3,295 tonne State Shipping Service vessel that worked the West Australian coast in the early part of the 20th century. In 1959 her hull was cut down and filled with limestone which was extended landward to form part of the jetty.

|

83

Cockburn Sound from 'SS Kwinana'

See photo 26 for overview of the remains of the 'SS Kwinana'.

|

84

Noongar Fish Trap

Traditional fishing practices of Noongar people included the use of fish traps represented here by this mosaic. fish and other marine animals were attracted through the trap entrance at high tide or driven in by dolphins called to assist by Noongar fishers. As the tide receded, marine life was trapped and consumed or used for other cultural purposes.

|

85

Noongar Fish Trap at Kwinana Beach

The Noongar Fish Trap and mosaic was constructed by Aboriginal art students from Challenger TAFE-Rockingham through generous support from the Town of Kwinana, BHP Billiton-Nickel West, the Department of Local Government and Regional Development and the Swan Catchment Council.

|

86

Another view of Noongar Fish Trap

Located at Wells Park, Kwinana Beach.

| |