1

Recently while cleaning my airbrush, I had a small part roll off the sink and down the drain. Mentally kicking myself, I knew that I had to find a better way. Around the holidaze, people send many gifts in tins similar to this. It's an odd size, it won't fit easily on a workbench shelf, so it's not fitting to store small parts, but it is just what I need for a small parts cleaner.

|

2

I drill some small holes around the rim. Three or four should suffice.

|

3

After drilling holes through the top and bottom, just in from the edge, I cut out the centers with a sabersaw.

|

4

I finish it off with tin snips, to keep the metal from getting distorted by the up and down motion of the saw.

|

5

Now I trim the edges to keep them more uniform. It probably would have been easier to do the whole thing by hand, but live and learn...

|

6

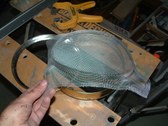

Now I've got a couple of interlocking hoops.

|

7

I lay it atop some aluminum screen used to replace storm windows. I chose the aluminum in case I ever need to dip anything in solvents, the nylon screening could deteriorate over time.

|

8

Before I go any further, I file down the sharp edges to keep the blood on the inside of my fingers.

|

9

Always looking to cut corners, I switch to a Dremel tool to speed up the process.

|

10

Now I snip the top edges about every 3/4 of an inch, so I can fold them down.

|

11

Once that's finished, I lay the screen over the bottom piece, and squeeze the top over it.

|

12

I trace the outline with a Sharpie pen to mark the circle. I'll cut it out with tin snips, but a sharp pair of scissors can be used if need be. Just don't try to cut anything afterwards, they'll be as dull as reruns of "Friends".

|

13

Now it's time to fit the pieces together. Try to align the holes as closely as possible before you do this, it won't be easy afterwards.

|

14

I run a bead of silicone adhesive around the rim.

|

15

After compressing the three sections, I put in the small screws to keep it together.

|

16

Voila! A screen that will allow you to put small parts in without risking them going down the drain, or to the bottom of a solvent bath.

|

17

The top view. If need be, it would be easy to rig up a handle that will allow you to dip the pieces without getting your mitts into any harsh cleaners. I don't think I'll be needing that. Most of the materials I had lying around my workshop, I invested eight dollars for the aluminum screening and sunk about two hours into the project. Not a bad trade off.

| |